In the world of manufacturing, achieving high precision, efficiency, and consistency is crucial. Whether you are building a single prototype or mass-producing components, maintaining high standards in every step of the process is essential. This is where a JIG—a custom-made tool used to control the location and motion of another tool—comes into play. JIG are indispensable in the manufacturing and assembly processes for positioning, guiding, and holding workpieces in place while operations like drilling, cutting, welding, or assembling are performed.

Precision and Accuracy: JIG are primarily used to enhance the precision and accuracy of repetitive operations. By providing a consistent setup for each workpiece, they ensure that every piece is machined or assembled exactly to specifications, which is especially important when working with complex or intricate parts.

Increased Productivity: Using JIG significantly reduces the time and effort required for setup. Workers don’t need to manually adjust the position of the workpiece for every operation, as the JIG holds the workpiece securely and in the correct position for each step. This leads to faster production cycles and improved efficiency.

Reduced Human Error: JIG minimize the chance of human error during production. With the workpiece securely positioned and guided, operators are less likely to make mistakes, ensuring high-quality results with every operation. This is particularly useful in industries where the tolerance level is critical, such as aerospace or automotive manufacturing.

Consistency in Production: Especially in mass production environments, consistency is key. JIG help to achieve uniformity across all parts by ensuring that each workpiece undergoes the same steps, in the same sequence, with the same precision. This standardization is essential for large-scale operations where many identical parts are needed.

Safety JIG also improve safety on the shop floor. By securely holding the workpiece, the chances of an operator being injured from flying debris, tool malfunction, or accidental contact with moving parts is minimized. In high-speed operations, where there’s a lot of motion and vibration, JIG can help stabilize the workpiece, preventing dangerous situations.

There are several different types of JIG, each designed to cater to specific production processes.

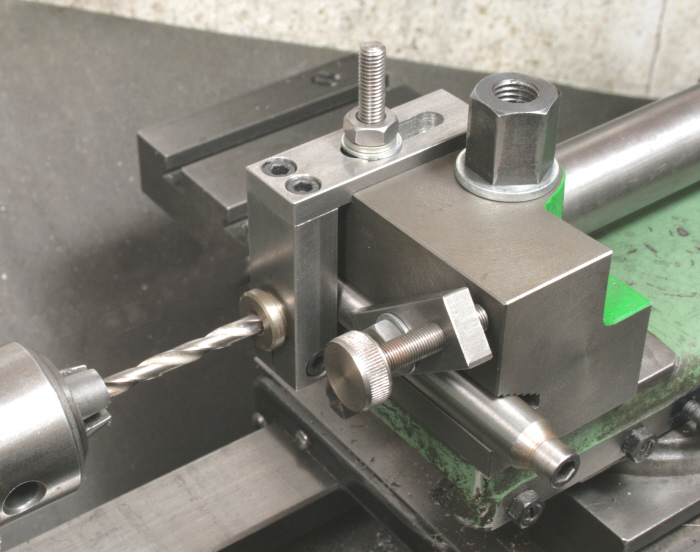

1. Drill JIG

As the name suggests, drill JIG are used to guide drills to the correct position for drilling holes. These JIG can be simple or complex, depending on the size and number of holes to be drilled.

Simple Drill JIG: Used for drilling one hole in a single piece of material.

Template JIG: A simple drill jig that uses a template to guide the drill bit for precise hole placement.

Plate JIG: Involves a metal plate that holds the workpiece and guides multiple drills to several points on the same piece, often used in mass production.

2. Boring JIG

Similar to drill JIG, boring JIG are used for enlarging or finishing a hole to a precise diameter. They guide the boring tool along the workpiece with high accuracy. Boring JIG are frequently used when a hole needs to be re-sized or smoothed out after an initial drilling process.

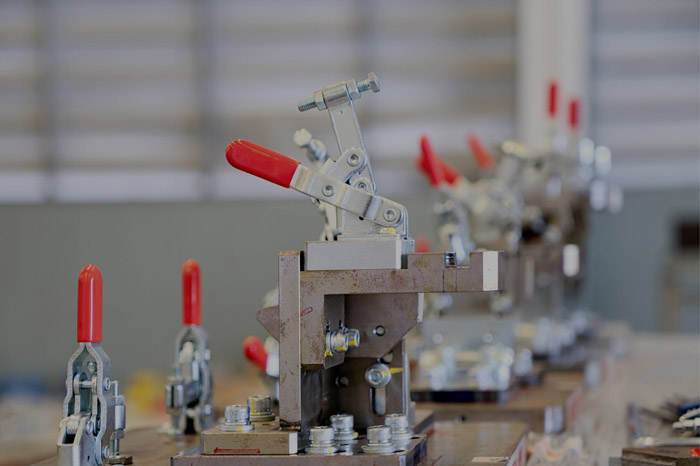

3. Welding JIG

Welding JIG are used to hold parts in place during the welding process. These JIG ensure that parts are properly aligned and securely positioned before welding, reducing the chances of warping, misalignment, or distortion during the welding process.

Fixed Welding JIG: These hold the workpieces stationary and are used for simple welding jobs.

Adjustable Welding JIG: These allow for adjustments and are ideal for parts of varying sizes or configurations.

4. Assembly JIG

In the assembly process, JIG are used to hold parts in place while they are being assembled. These JIG help to align multiple components accurately, ensuring that the final product is assembled correctly and with precision.

Pneumatic or Hydraulic JIG: These utilize pressurized air or fluid to clamp the workpiece securely during assembly, making them ideal for complex or large parts.

5. Check or Inspection JIG

These JIG are used to verify the accuracy and dimensions of a workpiece. They are typically used in quality control settings to ensure that the part meets specifications before it moves to the next stage of production. Inspection JIG can include fixed templates and gauges to measure things like hole placement, edge dimensions, and overall geometry.

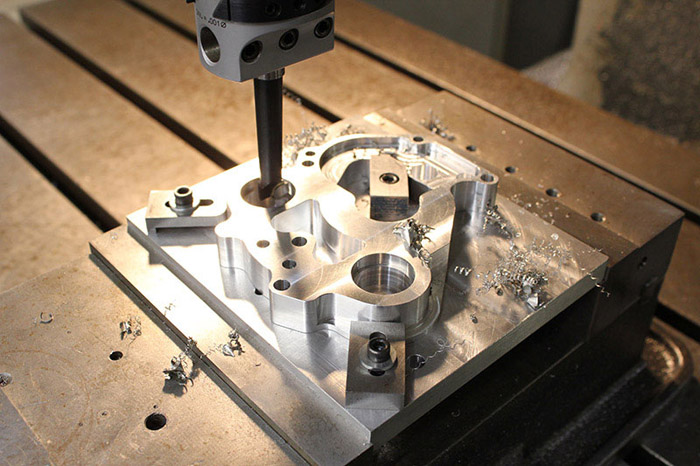

6. CNC JIG

CNC JIG are designed for use with CNC machines. They provide precise positioning for workpieces in automated manufacturing processes. These JIG often incorporate sophisticated features such as adjustable clamps and tool guides, which allow for high levels of automation and precision.

7. Fixture JIG

A fixture JIG is an assembly tool that combines both a fixture (which holds the workpiece in place) and a JIG (which guides the tool). It is used for more complex machining tasks like milling or turning, where the workpiece needs to be held securely in place and the tool needs to be guided along specific paths.

JIG play a vital role in modern manufacturing, providing precision, efficiency, and consistency across a variety of operations. Whether you are drilling holes, welding parts, or assembling products, JIG help ensure that each step is performed with accuracy, minimizing human error and optimizing production processes. With different types of JIG designed for specific tasks, manufacturers can choose the right tool for their needs to improve productivity, reduce costs, and maintain high standards of quality.