CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry by providing high precision, repeatability, and automation in producing complex parts. Among the various materials used in CNC machining, aluminum and its alloys are some of the most commonly chosen due to their unique properties.

It is the third most abundant element in the Earth's crust and is prized for its versatility across various industries. Here are some characteristics of Aluminum below.

Aluminum is significantly lighter than other metals like steel, which makes it ideal for applications where weight reduction is crucial, such as in aerospace and automotive industries.

Aluminum naturally forms a thin oxide layer on its surface, which protects it from corrosion. This property makes it suitable for outdoor applications, such as in marine environments or the production of consumer electronics.

Aluminum has excellent thermal and electrical conductivity, making it an excellent choice for applications like heat exchangers, electrical components, and wiring systems.

Although it is lightweight, aluminum is strong enough to withstand many mechanical stresses. When alloyed with other metals like copper, magnesium, or zinc, its strength can be further enhanced.

Aluminum is easy to shape and form, making it ideal for CNC machining. It can be cut, drilled, and milled with high precision, allowing for the production of intricate parts with tight tolerances.

Aluminum is 100% recyclable without loss of quality, making it an environmentally friendly choice for manufacturers looking to reduce waste and improve sustainability.

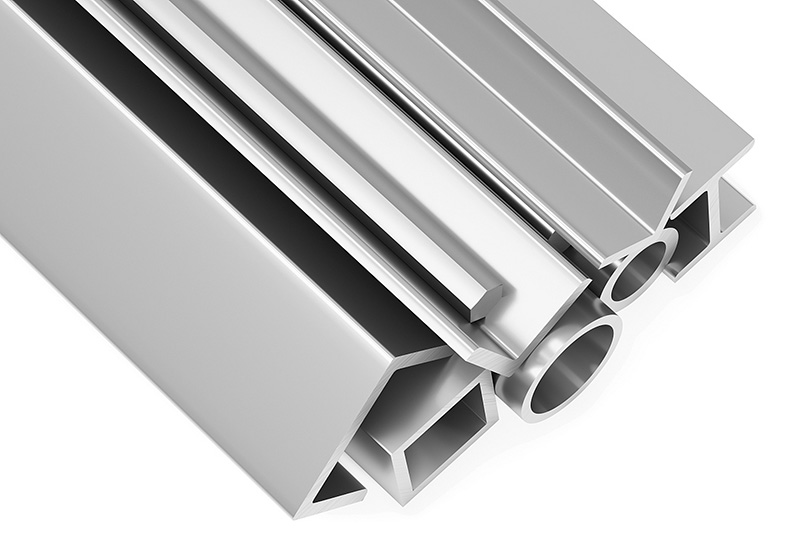

Aluminum alloys are classified into several series based on their composition and properties. The most commonly used aluminum alloys in CNC machining include:

Comprising 99% or more aluminum, this series is highly corrosion-resistant and has excellent workability. However, it has lower strength compared to other alloys. It's typically used in applications where corrosion resistance is more important than strength, such as in chemical processing equipment.

These alloys are known for their high strength but are prone to corrosion. They are often used in the aerospace industry for structural components, where strength is paramount.

These alloys offer good corrosion resistance and moderate strength. They are commonly used in the production of roofing, siding, and heat exchangers.

These alloys are known for their excellent corrosion resistance, especially in marine environments. They are commonly used in shipbuilding, automotive, and structural applications.

These alloys are highly versatile and offer a good balance of strength, corrosion resistance, and formability. They are widely used in construction, transportation, and consumer products.

Known for their exceptional strength, these alloys are often used in aerospace, military, and sports equipment applications, where high performance and durability are required.

CNC machining of aluminum involves using computer-controlled tools to remove material from a workpiece in a precise and controlled manner. The process typically involves milling, turning, drilling, and boring to produce parts with tight tolerances. Key advantages of CNC machining with aluminum include:

CNC machines can produce intricate parts with tight tolerances, which is essential in industries like aerospace and medical device manufacturing.

Aluminum is easy to machine, and with the right cutting tools and conditions, high material removal rates can be achieved, making CNC machining of aluminum a fast and cost-effective process.

CNC machining allows manufacturers to produce customized parts according to specific design requirements, such as unique geometries or specific surface finishes.

Aluminum can be machined to a high-quality finish, making it suitable for applications where aesthetic quality or smooth surface finish is important, such as in consumer electronics and automotive components.

While aluminum is generally easy to machine, it is important to use the right cutting tools, as some alloys may cause excessive wear on tools. Using coatings and optimizing cutting parameters can help extend tool life.

Aluminum's unique properties make it suitable for a wide variety of applications across different industries. Some notable applications of aluminum in CNC machining include:

Aluminum alloys are extensively used in the aerospace industry due to their lightweight and high-strength properties. CNC machining is used to create components such as fuselages, wings, and engine parts.

Aluminum parts are commonly used in the automotive industry to reduce vehicle weight and improve fuel efficiency. CNC machining is used to produce engine blocks, wheels, chassis components, and other critical parts.

Aluminum is widely used in the electronics industry for heat sinks, enclosures, and other components due to its excellent thermal conductivity and lightweight properties. CNC machining ensures precise production of intricate electronic parts.

In the medical field, aluminum is used for producing surgical instruments, implants, and diagnostic equipment. Its biocompatibility, light weight, and ease of machining make it an ideal choice.

Aluminum is often used in the production of consumer goods like laptops, smartphones, and kitchen appliances. CNC machining is employed to create these items with high precision and quality finishes.

Due to its corrosion resistance, aluminum is commonly used in marine applications, such as boat hulls, propellers, and other components exposed to saltwater.