Surface treatment plays a crucial role in enhancing the functionality, durability, and aesthetics of various materials.

Electrolytic polishing is an electrochemical process that smoothens and brightens the surface of a metal. It involves immersing the metal workpiece in an electrolyte solution and passing an electric current through it. The anode is the workpiece to be polished, and the cathode is usually made of an inert material. As the current flows, the metal ions from the workpiece are dissolved into the electrolyte, and the surface becomes smoother and more reflective.

1. Preparation: The workpiece is cleaned thoroughly to remove any dirt, oil, or contaminants.

2. Immersion: The cleaned workpiece is immersed in the electrolyte solution.

3. Current Application: An electric current is passed through the solution.

4. Polishing: The surface of the workpiece is gradually polished as the metal ions are removed.

5. Rinse and Dry: After polishing, the workpiece is rinsed with water and dried.

Electrolytic polishing is commonly used on metals such as stainless steel, aluminum, copper, and brass. It is particularly effective on materials with a relatively smooth surface before treatment.

PVD finish stands for Physical Vapor Deposition finish. It is a vacuum deposition process that deposits a thin film of material onto the surface of a workpiece. The process involves vaporizing a source material in a vacuum chamber and allowing the vapor to condense and form a thin film on the workpiece.

1. Preparation: The workpiece is cleaned and placed in the vacuum chamber.

2. Evaporation: The source material is heated until it vaporizes.

3. Deposition: The vaporized material is transported to the workpiece surface and condenses to form a thin film.

4. Cooling and Removal: After deposition, the workpiece is cooled and removed from the chamber.

PVD finish can be applied to a wide range of materials, including metals, plastics, ceramics, and glass. It is commonly used on watch cases, jewelry, automotive parts, and cutting tools.

High-end watches, luxury jewelry, and decorative items often use PVD finish to achieve unique colors and finishes. In the automotive industry, PVD-coated parts such as wheels and trim pieces are popular for their durability and aesthetic appeal.

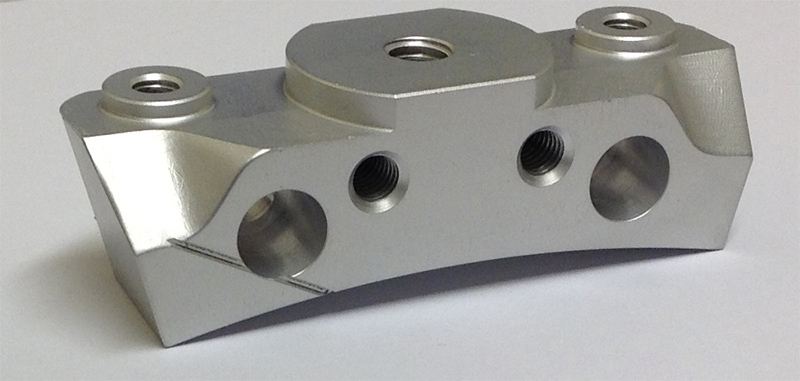

Bead blasting, also known as sandblasting or shot blasting, is a surface treatment process that uses small spherical beads or particles to clean, roughen, or texture the surface of a workpiece. The beads are propelled by compressed air or centrifugal force and impact the workpiece surface at high speed.

1. Preparation: The workpiece is cleaned and masked if necessary to protect certain areas from being blasted.

2. Blasting: The beads are sprayed onto the workpiece surface using a blasting gun or machine.

3. Inspection: After blasting, the workpiece is inspected for quality and uniformity.

4. Cleanup: Any remaining beads are removed from the workpiece surface.

3. Applicable Materials:

Bead blasting can be applied to almost any material, including metals, plastics, ceramics, and glass. It is commonly used on metal parts for cleaning, deburring, and creating a matte finish.

Each process has its own unique advantages and disadvantages, and the choice of process depends on the specific requirements of the product and the application. By understanding these processes, manufacturers can make informed decisions and choose the most appropriate surface treatment method to achieve the desired results.