The bending and forming of metal sheets are carried out on a bending machine. The workpiece to be formed is placed on the bending machine, and the brake shoe is lifted by a lifting lever. The workpiece slides to the appropriate position, and then the brake shoe is lowered onto the workpiece to be formed. The metal is bent and formed by applying force to the bending lever on the bending machine. The minimum bending radius is a function of the ductility and thickness of the formed metal. For aluminum plates, the bending radius of the metal should be greater than the thickness of the plate. When bending, due to a certain degree of rebound, the angle of metal bending is slightly larger than the required angle. The bending of metal sheets is carried out in the metal processing workshop.

Sheet metal bending is a stamping process that bends sheet materials, profiles, pipes or bars, etc. into a certain angle and curvature according to the design requirements to form the required shaped parts.

Bend the metal sheet into an L-shaped shape with an angle of 90° or non-90°. According to the processing, it can be divided into general processing (L > V/2) and special processing (L < V/2).

By bending the metal sheet twice or more times, it is folded into an N-shaped shape. N-shaped bending should adopt different processing methods according to different shapes. When bending, its internal dimension should be greater than 4 mm, and the size of the X dimension is limited by the shape of the mold. If the internal dimension of the material is less than 4 mm, special methods should be used for processing.

Also known as step bending, which is a bending of one positive and one negative. According to the angle, it is divided into beveled step and straight-sided step. The minimum size of the bending processing is limited by the processing mold, and the maximum processing size is determined by the shape of the processing machine. Generally, when the internal dimension of the Z-fold material is less than 3.5T, step dies are used for processing. When it is greater than 3.5T, the normal processing method is adopted.

Also known as reverse folding and flattening, the edge of the metal sheet is bent and then flattened to make it closely adhere to the surface of the sheet.

Riveting with Press: Use a bending machine to rivet hardware parts. Generally, auxiliary molds such as grooves and fixtures are used for processing. Generally, there are pressing nuts, pressing studs, pressing screws and some other hardware parts.

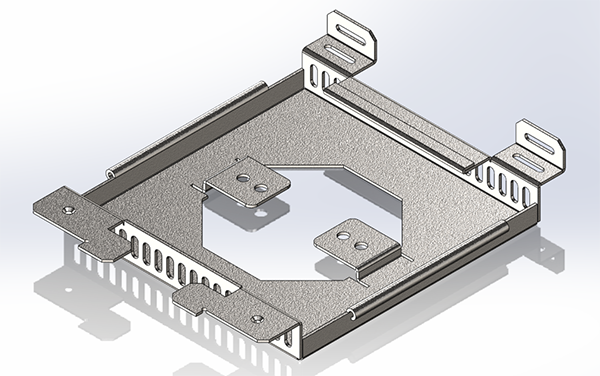

For some sheet metal parts with complex shapes and small sizes, the easy molding method can be used for processing. Generally, the processing of simple molds includes: small steps, hooks, bridges, bags, spring plates and some irregular shapes.