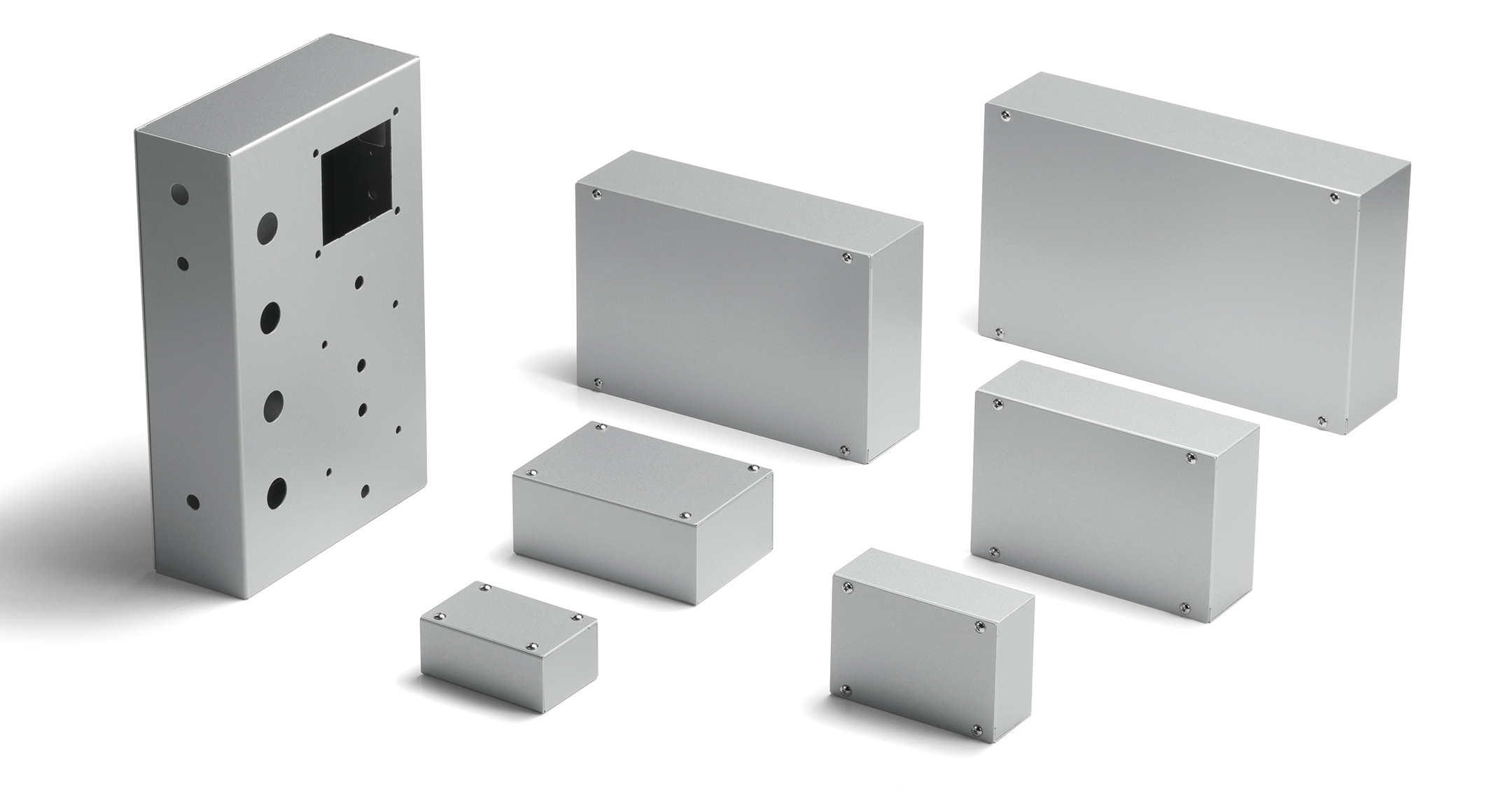

Enclosures come in a variety of forms, depending on the function and the environment in which they are used. The most common types of enclosures in sheet metal fabrication include:

Steel Enclosure: Steel is one of the most popular materials used for enclosures due to its strength, durability, and resistance to physical damage. Steel enclosures are ideal for industrial applications where high durability and protection against mechanical impact are required.

Aluminium Enclosure: Aluminium is lightweight yet strong and corrosion-resistant, making it an ideal material for enclosures in areas where weight reduction is important. Aluminium enclosures are commonly used in applications such as aerospace and telecommunications where both strength and lightness are crucial.

Medical Device Enclosure: These enclosures are specifically designed to protect sensitive medical equipment. Medical device enclosures must meet stringent regulations for safety, performance, and electromagnetic shielding. Materials used include stainless steel and aluminum, depending on the application.

Electrical Box Enclosure: Electrical box enclosures are used to house and protect electrical wiring, outlets, and devices. They are often made from steel or aluminum to prevent electrical hazards and provide resistance to fire, moisture, and physical damage.

The selection of material plays a vital role in the performance, durability, and cost-effectiveness of an enclosure. Several factors influence the choice of material, including environmental conditions, mechanical stresses, electrical requirements, and regulatory standards. Here's a look at some of the most commonly used materials in sheet metal enclosures:

Steel Enclosure: Steel is a strong and versatile material. It provides excellent protection against physical damage, and its magnetic properties make it ideal for electrical and electromagnetic shielding. However, steel can be heavier and more susceptible to corrosion if not treated properly.

Aluminium Enclosure: Aluminium offers a combination of strength and low weight, making it perfect for applications that require mobility or ease of handling. It is also highly resistant to corrosion, especially when anodized or coated. However, it might not provide the same level of impact resistance as steel, making it unsuitable for high-risk environments.

Stainless Steel for Medical Enclosures: Stainless steel is a preferred choice for medical device enclosures due to its resistance to corrosion and biocompatibility. Its hygienic properties make it ideal for environments where cleanliness is paramount, such as hospitals and laboratories.

Electrical Box Materials: For electrical boxes, the material must be non-conductive to prevent electrical hazards. Steel and aluminum are the most commonly used metals, but plastic enclosures are also available for less demanding applications. The material’s durability and fire resistance are key considerations in selecting the right electrical box enclosure.

Surface treatments are essential for improving the aesthetics, corrosion resistance, and overall performance of enclosures. Here are some common treatments applied to sheet metal enclosures:

Powder Coating: This treatment involves applying a dry powder to the surface of the metal, which is then cured under heat. Powder coating provides a durable, scratch-resistant finish that can be tailored in various colors and textures.

Anodizing: Commonly used for aluminum enclosures, anodizing creates a protective oxide layer on the surface, which enhances corrosion resistance and allows for color customization. It also increases the hardness of the aluminum.

Galvanizing: For steel enclosures, galvanizing involves coating the metal with a layer of zinc to prevent rust and corrosion. This is particularly useful in outdoor or harsh environments.

Polishing and Buffing: Stainless steel and aluminum enclosures often undergo polishing and buffing to achieve a smooth, reflective surface. This treatment improves aesthetics and also enhances corrosion resistance, especially in medical or food-related industries.

Enclosures are used across various industries, each requiring specific features to protect the internal components. Below are some common applications:

Steel Enclosures in Industrial Equipment: Steel enclosures are widely used in industries that require rugged, durable protection for heavy machinery, electrical circuits, and control panels. Steel is perfect for protecting sensitive equipment from external physical damage.

Aluminium Enclosures in Aerospace and Telecommunications: Aluminium enclosures are frequently found in aerospace applications, where weight reduction is essential without sacrificing strength. Additionally, they are used in telecommunications for housing wireless systems, antennas, and other equipment exposed to the elements.

Medical Device Enclosures: Medical devices require enclosures that ensure safety, durability, and compliance with medical standards. Materials like stainless steel and aluminum provide necessary protection against electromagnetic interference and are resistant to chemicals and sterilization processes.

Electrical Box Enclosures: Electrical box enclosures are used in residential, commercial, and industrial electrical systems to protect wiring, switches, and circuit boards. These enclosures ensure safety by preventing accidental contact with live wires and shielding components from dust, moisture, and physical damage.