Stainless steel is a cornerstone material in modern manufacturing, recognized for its strength, corrosion resistance, and versatility. From high-temperature industrial applications to precision machining, stainless steel offers grades tailored for specific needs.

Designed for High-Temperature Applications. A titanium-stabilized austenitic alloy. It’s specifically engineered to resist intergranular corrosion caused by exposure to high temperatures (up to 870°C). Key benefits include:

Ideal for applications requiring prolonged exposure to heat, such as aircraft exhaust systems, thermal oxidizers, and heat exchangers.

While not as corrosion-resistant as 316 stainless steel, 321 performs well in most industrial environments.

Ensures structural integrity in extreme heat.

This makes 321 stainless steel the material of choice for high-stress environments where thermal and mechanical stability are critical.

Superior Corrosion Resistance. Often referred to as marine-grade stainless steel, 316 stainless steel is prized for its ability to withstand harsh, chloride-rich environments. Its properties include:

Performs exceptionally well in saltwater, chemical processing environments, and areas exposed to acidic compounds.

Remains stable at high temperatures, making it suitable for heat exchangers and boilers.

Enhances its resistance to pitting and crevice corrosion, especially in marine or chemical applications.

Machinability and Versatility. 416 stainless steel stands out among martensitic grades for its exceptional machinability. It is a free-machining alloy with properties that cater to industries requiring high production rates.

Enhanced by sulfur content, allowing for faster and more precise cutting.

Best suited for environments with minimal exposure to harsh chemicals or moisture.

Strong, wear-resistant, and suitable for high-load applications.

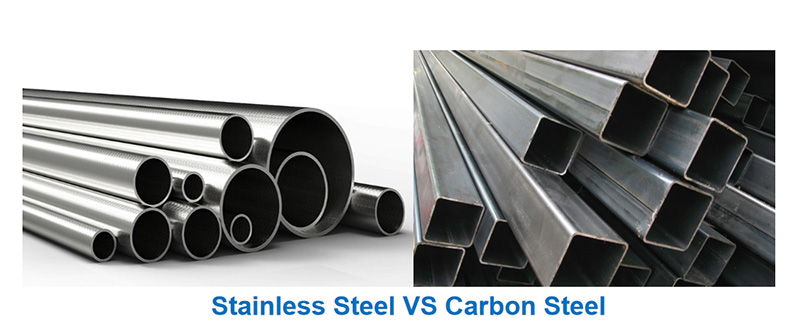

Stainless Steel: Contains chromium (usually over 10.5%), forming a protective oxide layer that prevents rust. Ideal for outdoor, marine, and industrial environments.

Carbon Steel: Lacks corrosion resistance and is prone to rust unless coated or painted.

Stainless Steel: Offers high strength and retains it over time. Grades like 316 and 321 perform well under stress and heat.

Carbon Steel: Often stronger in tensile applications but may require maintenance due to rusting.

Stainless Steel: Higher upfront cost but lower long-term maintenance.

Carbon Steel: Cheaper initially, but long-term expenses for rust prevention and repair may add up.

Stainless Steel: Best for environments demanding corrosion resistance, such as kitchens, factories, and outdoor settings.

Carbon Steel: Preferred for structural applications like beams, pipelines, and tools where cost and tensile strength are priorities.

Cutting stainless steel requires the right tools and techniques to manage its toughness and resistance to heat.

Advantages: Ideal for intricate patterns, high precision, high efficiency, smooth cuts, material saving and no thermal deformation. Especially for thin sheets

Disadvantages: High cost, high energy consumption, limited effect on thick plates, and need to prevent thermal effects and reflection problems.

Advantages: Fast speed, low cost, suitable for thick plates, easy to operate and portable.

Disadvantages: Generates heat, which will cause minor warping.

Advantages: This process is more precise than traditional methods, less noise and vibration and less dust created while cutting.

Disadvantages: Need manual labor. Slow and inefficient. The quality of the end result is hard to control.

Advantages: Able to achieve high precision, can produce complex shapes and cuts, good surface finish, dust-free and harmless to the environment.

Disadvantages: Cannot be used for very thick materials, high initial investment and high time cost.