Stainless steel is defined in GB/T20878-2007 as steel with stainless and corrosion resistance as its main characteristics, and a chromium content of at least 10.5% and a carbon content of no more than 1.2%.

Stainless steel is resistant to weak corrosive media such as air, steam, and water or has stainless properties is called stainless steel; and steel that is resistant to chemical corrosion media (acids, alkalis, salts, etc.) is called acid-resistant steel.

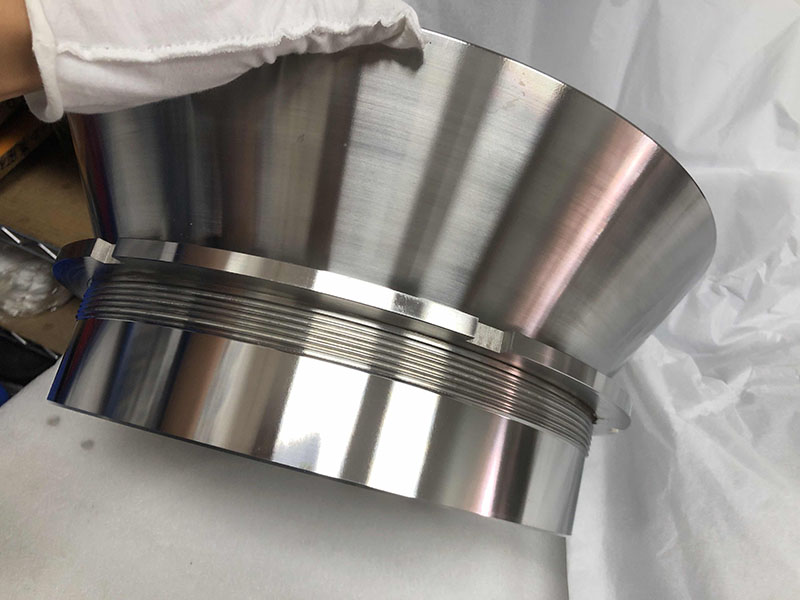

Polishing: polishing stainless steel is a common choice in many industries. Polishing improves the surface smoothness, giving stainless steel a shiny, mirror-like finish. It removes scratches and imperfections, enhancing the material's aesthetics and corrosion resistance.

Sandblasting: This process uses high-speed abrasive particles to clean or texture the surface, creating a uniform matte finish. Sandblasting is often used to prepare surfaces for further treatment or to achieve a decorative appearance.

Passivation: Passivation involves treating stainless steel with a mild oxidizing agent, such as nitric or citric acid, to remove surface contaminants and enhance its corrosion resistance by forming a thin, protective oxide layer.

Degreasing and rust removal: This treatment removes oils, grease, and rust from the surface using solvents or chemical cleaners, preparing the material for subsequent processes.

Pickling: Pickling involves immersing stainless steel in a solution of acids (typically nitric and hydrofluoric acids) to remove oxide layers, scales, and surface impurities, restoring its original metallic appearance and ensuring a clean surface.

Electroplating: Electroplating coats the stainless steel surface with a thin layer of another metal, such as chromium, nickel, or gold, to improve its appearance, durability, or corrosion resistance.

Electrolysis: Electrolysis uses an electric current to remove contaminants or polish the surface. It is commonly used for brightening stainless steel in high-end applications.

Spray coating: This method applies a protective or decorative layer of material, such as paint, powder coating, or ceramic, to the stainless steel surface, enhancing its aesthetics and providing additional corrosion resistance.

PVD coating: PVD coating deposits a thin, hard, and durable layer of material, such as titanium nitride or zirconium, onto the stainless steel surface. It improves wear resistance, enhances appearance, and provides a variety of color options.

2B finish is a common surface treatment method with high surface quality, silvery white color, good gloss and mirror effect. It has good anti-rust and corrosion resistance, and also has certain anti-fingerprint performance. It is often used in occasions requiring high gloss and smoothness.

2D finish is a rough surface treatment method with a matte gray or black appearance. The advantages of 2D surface treatment are strong anti-fingerprint and anti-rust capabilities, and relatively low cost. It is often used for structural parts and support parts that require high strength and durability.

4B finish is a more advanced surface treatment method with extremely high surface quality, extremely high gloss, and mirror finish. It is suitable for occasions that require excellent surface quality and gloss, such as high-end tableware, luxury buildings, etc.

BA finish is a special surface treatment method, also known as "super polishing", with a silvery white or gray appearance, and extremely high gloss and mirror finish. It is suitable for high-end decoration, luxury buildings and other occasions that require excellent surface quality and gloss. At the same time, BA surface treatment also has strong fingerprint resistance and corrosion resistance.

NO.4 finish is a common surface treatment method, also known as "sand grain" or "satin grain", with a matte gray or black appearance. The advantages of NO.4 surface treatment are strong anti-fingerprint and anti-rust capabilities, and relatively low cost. It is often used in ordinary buildings, furniture and other occasions that require a certain degree of rust resistance and gloss. In addition, NO.4 surface treatment also has a certain decorative effect, which can bring people a warm and comfortable visual experience.