China sheet metal fabrication parts have diverse applications in the manufacturing of aircraft structural parts. Different types of aircraft structural parts require corresponding China sheet metal fabrication parts based on their function and morphological characteristics.

Fuselage Shell

The fuselage shell is one of the most important structural parts of an aircraft, usually made with aluminum alloy China sheet metal fabrication parts. Aluminum alloy offers excellent strength and lightweight properties, making it suitable for large structural components. Using China sheet metal fabrication parts, aluminum alloy plates can be processed through cutting, bending, deep drawing, and other techniques to create fuselage shells that meet design requirements, ensuring the overall strength and stability of the aircraft structure.

Winglets

Winglets are crucial components of an aircraft, mainly responsible for lift and control during flight. China sheet metal fabrication parts play a significant role in the manufacturing of winglets. Aluminum alloy or composite materials can be shaped through stamping, deep drawing, and other processes to achieve complex curved wing structures, ensuring aerodynamic performance and strength requirements for the winglets.

Cabin Doors

Cabin doors are important passageways for passengers to enter and exit the aircraft cabin, typically made using titanium alloy or composite materials via sheet metal forming. Titanium alloy offers excellent high-temperature and corrosion resistance, suitable for structural parts like cabin doors that need to endure high strength and safety requirements. Through China sheet metal fabrication parts, complex shapes and sealing requirements of cabin doors can be achieved, enhancing the lifespan and safety of the doors.

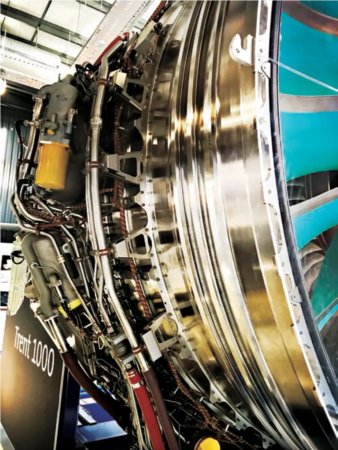

Air Inlets

The air inlet is located at the front of the engine and is responsible for bringing in air for engine combustion. It is usually made of composite materials using China sheet metal fabrication parts. Composite materials have excellent heat resistance and impact resistance, making them suitable for manufacturing air inlet structural components that function under high temperatures and high-speed air pressure. Using China sheet metal fabrication parts, lightweight designs and complex curved structures of the air inlets can be achieved, improving the aerodynamic performance of the aircraft.

Material Selection and Performance Matching

China sheet metal fabrication parts are typically used in the processing of aviation-specific materials such as aluminum alloys, titanium alloys, and composite materials. By utilizing China sheet metal fabrication parts, the shape and performance of materials can be effectively controlled to meet requirements for strength, stiffness, and corrosion resistance of aircraft structural parts. Correct material selection and matching with China sheet metal fabrication parts can enhance the overall performance of structural parts.

Structural Optimization Design

Utilizing China sheet metal fabrication parts enables the shaping of complex structural parts. Through sheet metal forming, lightweight designs of structural components can be realized, reducing their weight and enhancing aircraft load capacity and fuel efficiency. Additionally, sheet metal forming can achieve aerodynamic optimization designs for structural components, improving flight performance and stability.

Forming Process Impact

Different China sheet metal fabrication parts processes such as shearing, stamping, bending, and deep drawing have varying degrees of impact on structural part performance. For example, the stamping process can form complex curved structures but may introduce stress concentrations; the bending process can enhance the strength of structural parts but may cause material deformation or damage. Therefore, when selecting forming processes, it is necessary to consider the specific requirements of structural parts and balance performance with process considerations.

Surface Treatment and Coating

Structural parts manufactured using China sheet metal fabrication parts require surface treatment and coating during use to improve their corrosion resistance, wear resistance, and appearance quality. Proper surface treatment can enhance the weather resistance and mechanical properties of structural parts, extend their lifespan, and improve the overall performance of the aircraft.