Perforated aluminum panels have become an essential component in the filtration industry due to their numerous benefits. These panels are widely used in various filtration processes to ensure efficient and effective separation of solid particles from liquids or gases. In this blog, we will explore the importance of perforated aluminum panels in the filtration industry and how they contribute to better filtration performance.

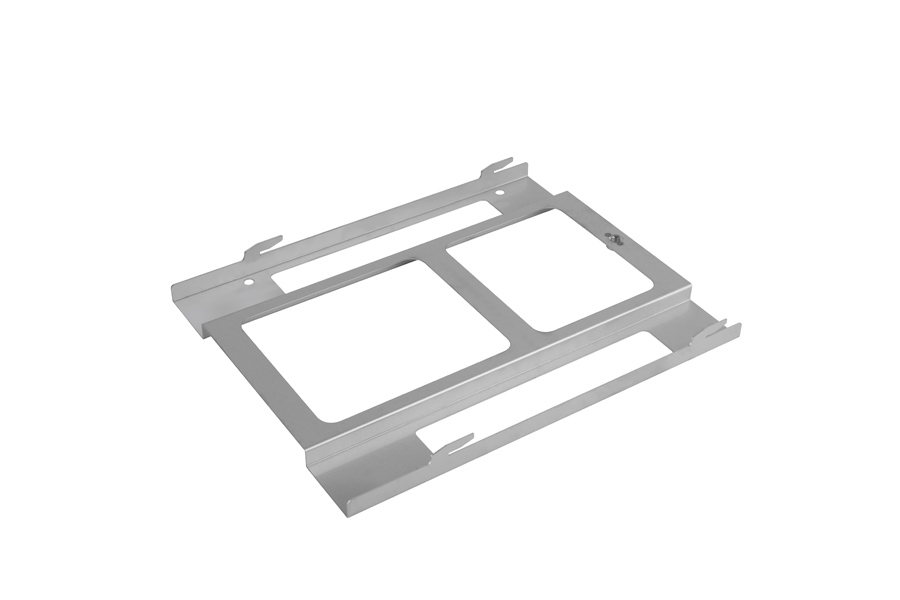

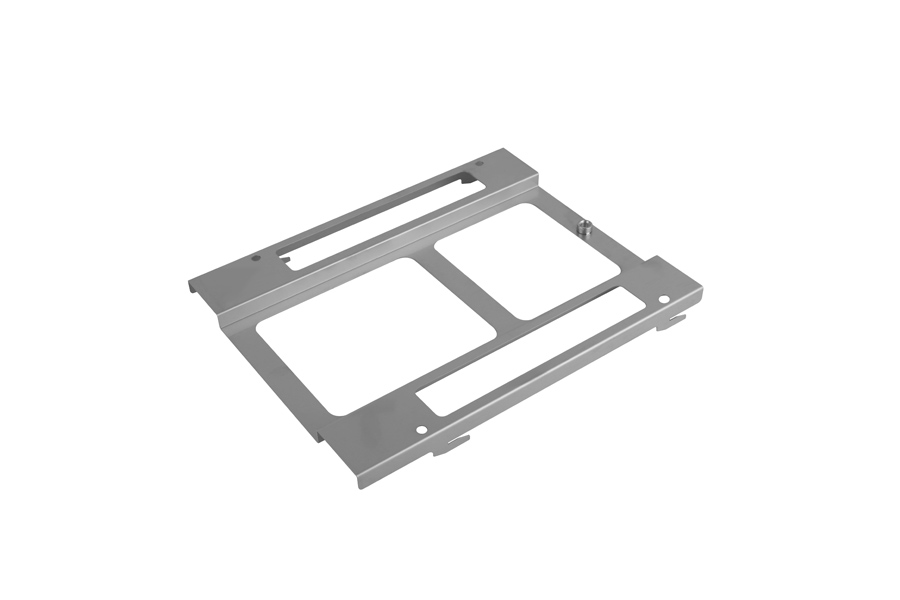

Perforated aluminum panels are sheets of aluminum that are punched with small holes in a regular pattern. These holes allow the passage of liquids or gases while retaining solid particles, making them ideal for filtration applications. The panels can be customized to suit specific filtration requirements, with different hole sizes, shapes, and spacing options available.

Perforated aluminum panels offer several advantages in filtration processes. Firstly, they provide excellent strength and durability, ensuring long-lasting performance in demanding filtration applications. The panels are also lightweight, making them easy to install and handle. Additionally, the corrosion-resistant properties of aluminum make these panels suitable for use in a wide range of environments.

Furthermore, perforated aluminum panels allow for high flow rates, enabling efficient filtration of liquids or gases. The perforations can be designed to achieve optimal filtration efficiency, ensuring the desired separation of particles. With proper customization, these panels can effectively remove contaminants and impurities from the filtration medium, resulting in cleaner and purer output.

Perforated aluminum panels are used in various filtration processes across different industries. They are commonly employed in water treatment systems, where they help remove solids and debris from incoming water sources. In air filtration systems, these panels assist in trapping dust, pollen, and other airborne particles to improve indoor air quality. Additionally, perforated aluminum panels are utilized in oil and gas filtration to separate contaminants and impurities from the extracted fluids.

One of the key advantages of perforated aluminum panels is their flexibility in customization. Manufacturers can tailor the panels to meet specific filtration requirements, such as adjusting hole size and pattern to achieve the desired filtration efficiency. Recent innovations in perforated aluminum panel technology have also led to the development of advanced coatings and surface treatments that enhance the panels' performance and longevity.

In conclusion, perforated aluminum panels play a crucial role in the filtration industry by offering strength, durability, and efficient separation of particles. These panels are widely used in water treatment, air filtration, and oil and gas filtration applications, where they contribute to cleaner and purer output. With ongoing customization and innovation, perforated aluminum panels continue to be a vital component in ensuring effective filtration processes.