Powder coating is a spraying technique widely used on surfaces of various materials such as metal, plastic, and wood, especially in industrial and decorative coatings. The powder coating process not only provides a variety of visual effects, but also significantly improves product performance and durability. Depending on the type of powder, coating method and coating conditions, the surface effect of powder coating can take on various forms.

In the field of coatings and surface treatment, Flat Effect, Sand Textured and Orange Peel are some of the most common surface effects.

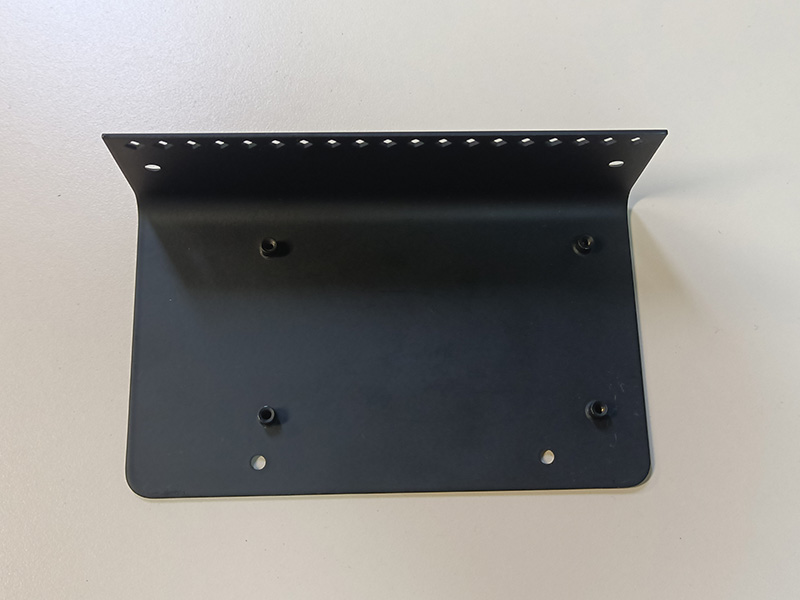

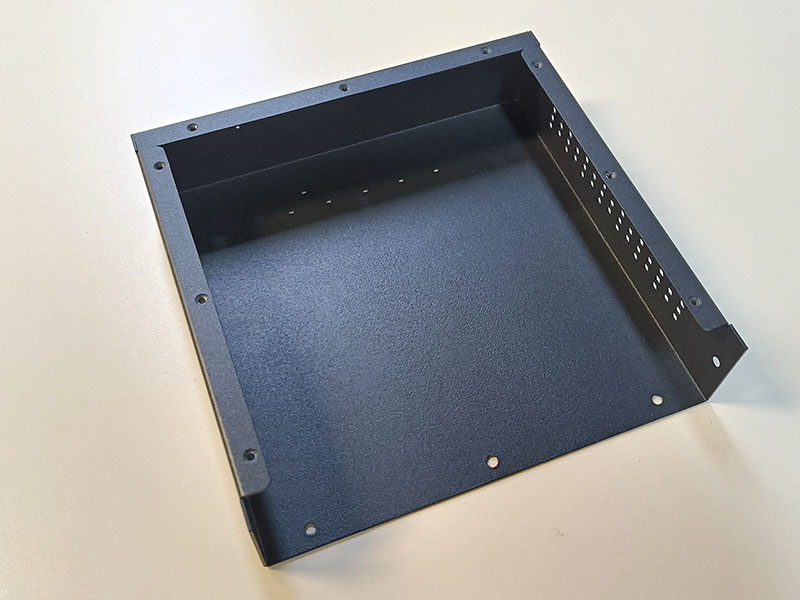

Gloss: Flat Effect is a surface effect with little or very low gloss, usually with a matte or non-glossy appearance.

Surface Texture: The surface of this coating is very smooth, showing a minimalist, clean effect without light reflections.

Visual Effect: Due to the lack of glossy reflections, Flat Effect gives a gentle and soft visual experience, suitable for emphasizing the color itself rather than the surface reflection.

Reduces fingerprints and stains: Flat effect coatings are less likely to show fingerprints and stains, so they are suitable for applications where a clean appearance needs to be maintained for a long time.

Modern and simple aesthetics: Flat Effect gives a modern and simple aesthetic, suitable for modern homes, offices and certain artworks.

Hide surface imperfections: Flat coatings are generally good at hiding minor imperfections in the substrate, so they are often used for coating walls or furniture surfaces

Surface texture: This effect creates a rough, gravel-like texture, with a grainy feel that resembles the touch of fine sand.

Visual effect: The surface looks a bit like it is covered in sand grains, and light is scattered on the surface so it does not reflect into a smooth sheen.

Application: Sand texture is often seen on walls, furniture or outdoor items, especially those where durability and visual interest are required.

Enhanced durability: Sand texture coatings have a certain wear resistance and are suitable for high-traffic areas or outdoor environments, such as exterior walls, door frames and other exposed surfaces.

Hide defects: Due to the presence of particles, sand texture can effectively hide small surface defects, cracks or irregularities, giving the surface of the object a more uniform appearance.

Provide anti-slip effect: Sand texture coatings can provide a certain anti-slip performance, especially on some floors or work surfaces, which can enhance the safety of use.

Unique visual effect: Sand texture can add visual and tactile depth and texture to the coating, adding uniqueness to the decoration.

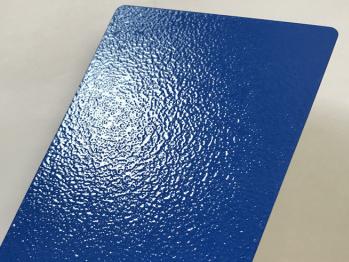

Surface texture: Orange peel is named for its orange peel-like bumps and ridges, which are usually formed when the paint fails to flow or dry smoothly during the spraying process.

Visual effect: This surface looks like orange peel, with a noticeable graininess, usually slight bumps and depressions, and irregular shapes.

Application: Orange peel is widely used in automotive coatings, home appliance coatings, furniture and architectural coatings, especially when it is necessary to increase the surface texture or have a specific visual effect.

Enhanced durability: Orange peel coatings are generally more durable than smooth surfaces and can effectively resist wear, scratches and weather changes.

Balance of beauty and practicality: Although the orange peel effect is more unique in appearance, it also retains a certain aesthetic and practicality, especially for surfaces with high appearance requirements and durability such as cars or furniture.

Hide defects: Due to the uneven surface, the orange peel effect helps to hide surface blemishes and irregular defects, making the surface look more uniform.

Reduce reflection: The orange peel effect reduces light reflection through the concave and convex shape of the surface, avoiding the reflection interference that may be caused by smooth coatings. It is suitable for occasions that require low reflection or high visual effects.