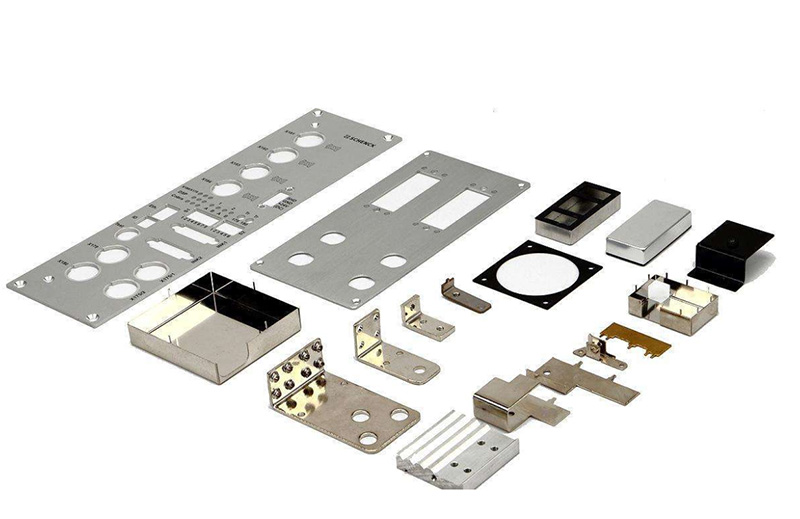

Sheet metal fabrication refers to the process of transforming flat sheets of metal into functional components through cutting, bending, welding, and other techniques.

HSJ can provide sheet metal processing services including welding, finishing and insert installation of aluminum, copper, steel and stainless steel. Working with domestic and international partners, we can handle any quantity from prototype to series production.

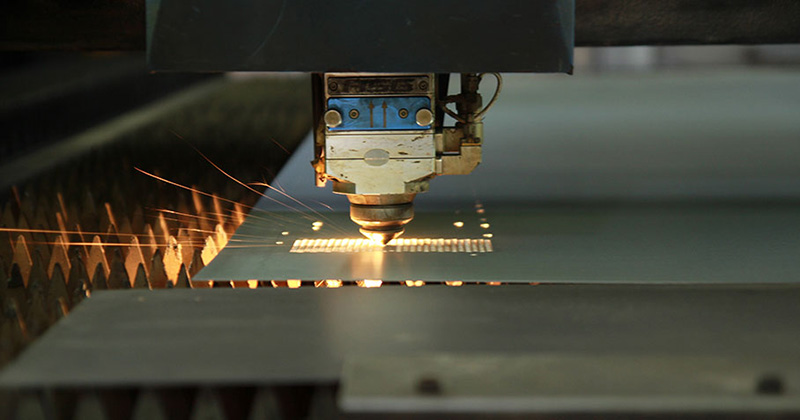

Cutting is one of the most fundamental processes in sheet metal fabrication. It involves separating metal sheets into desired shapes, sizes, and profiles.

Laser Cutting: Laser cutting uses a high-powered laser to melt, burn, or vaporize the material. It's known for its precision and ability to cut intricate patterns, including fine details and complex geometries. Laser cutting is ideal for cutting thin to medium thickness sheets.

Water Jet Cutting: A water jet cutter uses a high-pressure stream of water, often mixed with abrasive materials, to cut through metal. This process doesn’t create heat, which means there's no risk of warping or distortion. Water jet cutting is excellent for cutting thick metals and materials sensitive to heat.

Plasma Cutting: Plasma cutting uses an electrically charged gas (plasma) to cut through metal. It’s faster than laser cutting and can handle thicker metals, but the edges may not be as smooth. Plasma cutting is typically used for metals like steel and aluminum.

Shearing: Shearing is a mechanical process that uses a pair of blades to cut straight lines through sheet metal. It's a fast and cost-effective method for cutting simple shapes and straight lines in thinner metal sheets.

Punching: Punching involves using a punch press and a die to create holes or other shapes in a metal sheet. The punch pushes the metal into the die, removing a slug of material. This process can create round holes, slots, and other standard shapes.

Prototyping refers to processes that reshape sheet metal without removing material, often by applying force or pressure to bend, stretch, or shape the metal.

Bending: Bending uses a press brake or other machines to bend metal sheets at a specific angle. It’s one of the most common forming processes and is used to create U-shaped, L-shaped, or V-shaped parts. The accuracy of the bend depends on factors like material type, thickness, and the tooling used.

Stamping: Stamping uses high-speed presses with dies to create parts by pressing the metal sheet into the desired shape. Stamping can include processes like:

Punching: Creating holes or other shapes in the sheet metal.

Embossing: Creating raised patterns or shapes on the metal.

Coining: A precise stamping process to create detailed impressions or markings.

Blanking: Cutting out a flat shape from the sheet metal, leaving a piece for further forming.

Roll Forming: In roll forming, the sheet metal is passed through a series of rollers that gradually shape it into a specific profile. Roll forming is continuous and is used to create long, uniform parts, such as channels, roofing materials, or metal sections used in construction.

Spinning: In this process, a metal sheet is clamped onto a lathe and rotated at high speed while a tool shapes it into a cylindrical or conical form. This is used to make products like bowls, cups, or round parts with symmetrical shapes.

In many fabrication projects, welding services play a crucial role in assembling sheet metal parts. Welding is the process of joining two or more pieces of metal using heat and pressure. It’s an essential step for creating robust, durable components that can withstand stress and wear over time.

MIG Welding (Metal Inert Gas): This is one of the most popular welding techniques used in sheet metal fabrication. It provides a clean, strong weld with minimal spatter and is ideal for both thin and thick sheet metal.

TIG Welding (Tungsten Inert Gas): TIG welding is known for its precision and ability to produce high-quality, clean welds. It’s commonly used when working with thin materials or for applications requiring a high degree of accuracy.

Spot Welding: This process is commonly used for joining thin sheets of metal together. It involves applying pressure and heat to small points on the metal to fuse them together, typically used in automotive and appliance manufacturing.

Arc Welding: Arc welding is another common method used for heavy-duty sheet metal fabrication. It is suitable for larger components and thicker materials and offers strong, reliable welds.

Powder Coating: Powder coating involves applying a dry powder to the metal surface, which is then heated to create a durable, smooth coating. It provides excellent protection against corrosion and gives a clean, even finish.

Electroplating and Galvanizing: Electroplating involves coating the metal with a thin layer of another metal (e.g., gold, silver, or chrome) to improve corrosion resistance and appearance. Galvanizing refers to the process of coating steel with a layer of zinc to prevent rust.

Anodizing: For aluminum parts, anodizing is a process that uses an electrolytic process to increase the thickness of the natural oxide layer, improving corrosion resistance and providing color options for aesthetic purposes.

Polishing and Buffing: This is the process of smoothing the surface of the metal, often resulting in a shiny or reflective finish. Polishing can be done mechanically with abrasives or chemically for a smoother, more consistent finish.

Customization: Fabricators can produce unique designs tailored to your specific needs, whether it's for a one-off prototype or a large-scale production run.

Cost-Efficiency: Sheet metal fabrication can be more affordable than other manufacturing methods, especially when working with high-volume production.

Durability: Metal parts are known for their strength and resilience, ensuring that the final products are built to last.

Speed: With modern technologies like CNC machines, laser cutting, and automated welding, manufacturers can produce high-quality parts quickly, reducing lead times.