Powder coating is a common operation in many industrial productions, especially in coating, surface treatment, furniture manufacturing and the production of some electronic products. Correct powder coating operation can not only improve production efficiency, but also ensure product quality and the safety of the working environment.

Different workpieces and use environments require the selection of appropriate powder coatings. According to the material, color requirements and external environmental factors (such as corrosion protection, UV protection, etc.) of the object, choose the right type of coating. Powder coatings are usually epoxy, polyester, acrylic, etc., and different types of coatings have different performance characteristics.

Before powder coating, make sure that the surface of the workpiece is clean and free of impurities such as oil, dust, etc. Cleaners can be used for cleaning to remove surface impurities, ensure uniform adhesion of powder coating, and improve coating quality.

The powder coating equipment should be fully inspected before use, including the inspection of the spray gun, powder sprayer, power line and air compressor to ensure that the equipment is operating normally and there are no faults.

Powder coating should be carried out in a well-ventilated environment to avoid accumulation and inhalation of powder coating. Choose a special powder coating room or equipment to ensure that the powder dispersion during the coating process is effectively controlled.

During powder coating, operators should wear appropriate protective equipment, including anti-static clothing, dust masks, goggles and gloves, etc., to reduce dust inhalation and skin irritation.

During the coating process, the distance between the spray gun and the workpiece should be kept consistent, generally between 15-25 cm. When coating powder, the operation should be carried out at a uniform speed and uniform angle to avoid excessive or uneven coating.

According to the surface material and powder coating amount of the workpiece, reasonably adjust the air pressure and paint flow rate of the powder coating equipment. Excessive pressure will cause powder to fly, and excessive flow rate will cause the coating to be too thick, affecting the coating quality.

During the powder coating process, special attention should be paid to avoid excessive accumulation of powder on the workpiece to avoid uneven coating, bubbles or shedding. The best effect can be achieved by repeated and uniform coating and layer-by-layer coating.

The humidity and temperature of the environment should be controlled during the powder coating process to prevent the paint from not being evenly attached or drying poorly. Generally speaking, it is best to keep the temperature at 18-25°C and the humidity below 50%.

After the powder coating is completed, the coating needs to be cured. Curing usually requires heating in an oven to completely harden the paint. The curing temperature and time should be determined according to the type of paint and the material of the workpiece, generally 150-200°C, and the curing time is 10-20 minutes.

After curing, the workpiece should be left to stand for a period of time to allow it to cool naturally to ensure that the coating does not crack due to temperature changes. After cooling, check the quality of the coating. If there are any unevenness or defects, they should be repaired.

After the powder coating is completed, clean the equipment and working environment in time. This includes cleaning the spray gun, the floor and walls of the spray room, removing dust, and keeping the working environment clean.

(Grinded)

→

(Anodized)

→

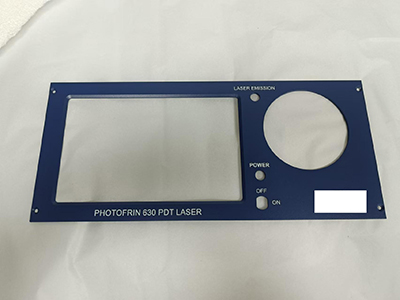

(Powder Coated)

Powder coating will generate a lot of dust, so a good ventilation and exhaust system is required. In order to prevent the accumulation of harmful gases and dust, they should be discharged outdoors in time or effective filtering measures should be taken.

During the powder coating process, powder coatings may generate static electricity, so special attention should be paid to fire and explosion prevention. The anti-static device of the equipment should be checked regularly to avoid fire or explosion caused by static electricity.

The waste generated during the powder coating process should be properly handled to avoid environmental pollution. It can be handled by a professional waste recycling and disposal company to ensure compliance with relevant environmental protection regulations.