Precision metal stamping is a silent hero in the realm of electronic manufacturing, orchestrating an intricate dance from sheets of metal to the creation of tiny yet critical chips. This article aims to demystify the fascinating world of precision metal stamping and its pivotal role in shaping the heart of electronic devices.

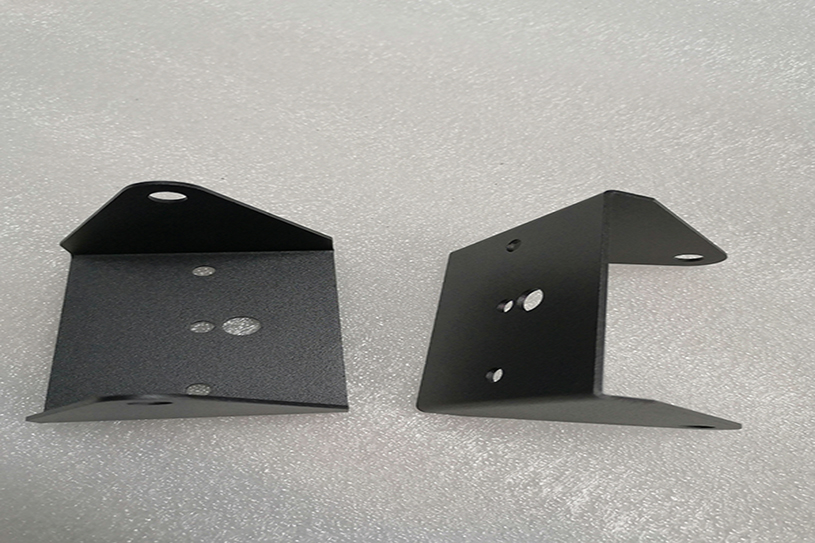

At the core of electronic manufacturing lies the precision metal stamping process. This intricate technique involves transforming flat sheets of metal into precise shapes and sizes, forming the backbone of electronic components. Through a combination of precision dies, molds, and mechanical force, manufacturers can achieve the exact specifications required for the intended electronic part.

One of the key contributions of high-precision custom sheet metal stamping is its role in the ongoing trend of miniaturization in electronic devices. As technology continues to advance, the demand for smaller and more powerful electronic components rises. Precision metal stamping allows manufacturers to create intricate patterns and designs on a micro scale, enabling the production of smaller, more efficient chips without compromising performance.

Ensuring the reliability and functionality of electronic components is paramount. Precision metal stamping plays a crucial role in maintaining quality standards throughout the manufacturing process. The use of advanced materials, rigorous quality control measures, and cutting-edge stamping technology ensures that each stamped metal piece meets the stringent requirements of electronic applications.

In addition to its technical prowess, precision metal stamping in electronic manufacturing brings environmental benefits. The process generates minimal waste, as manufacturers can optimize the use of raw materials with precision dies and molds. This efficiency not only reduces environmental impact but also contributes to cost-effectiveness in production.

In the intricate world of electronic manufacturing, precision metal stamping emerges as a transformative force, turning sheets of metal into the technological marvels that power our daily lives. From the meticulous process to its role in miniaturization and quality assurance, the journey from sheets to chips is a testament to the precision and innovation driving the electronic industry forward. As we continue to push the boundaries of what's possible in technology, precision metal stamping remains a steadfast ally, ensuring that the heart of our electronic devices beats with unparalleled accuracy and efficiency.