In the world of automotive engineering, the use of custom aluminum components has become increasingly essential. As technology advances and demands for more efficient and lightweight vehicles grow, manufacturers are turning to aluminum as a versatile material that offers both strength and flexibility. In this blog, we will explore the significance of custom aluminum components in automotive engineering and how they are revolutionizing the industry.

Aluminum is a popular material choice in the automotive industry for several reasons. Firstly, aluminum is lightweight, which helps to improve fuel efficiency and reduce emissions. This is crucial as automakers strive to meet stringent environmental regulations and consumer demand for greener vehicles. Additionally, aluminum is highly corrosion-resistant, ensuring longevity and durability in various weather conditions.

Furthermore, aluminum is easily moldable, making it an ideal material for creating custom components tailored to specific vehicle designs. This flexibility allows for the production of intricate and complex parts that may not be feasible with other materials. The ability to create custom aluminum components also opens up endless possibilities for innovation in automotive engineering.

Custom aluminum components are utilized in various parts of a vehicle, including the engine, transmission, chassis, and body. For example, aluminum is commonly used in engine blocks and cylinder heads to improve heat dissipation and reduce weight. Similarly, custom aluminum components are often found in suspension systems to enhance handling and performance.

In addition, custom aluminum components play a crucial role in safety features such as airbags, seat frames, and crash structures. The lightweight yet strong properties of aluminum make it an excellent choice for protecting occupants in the event of a collision. By incorporating custom aluminum components into safety systems, automakers can enhance the overall safety of their vehicles.

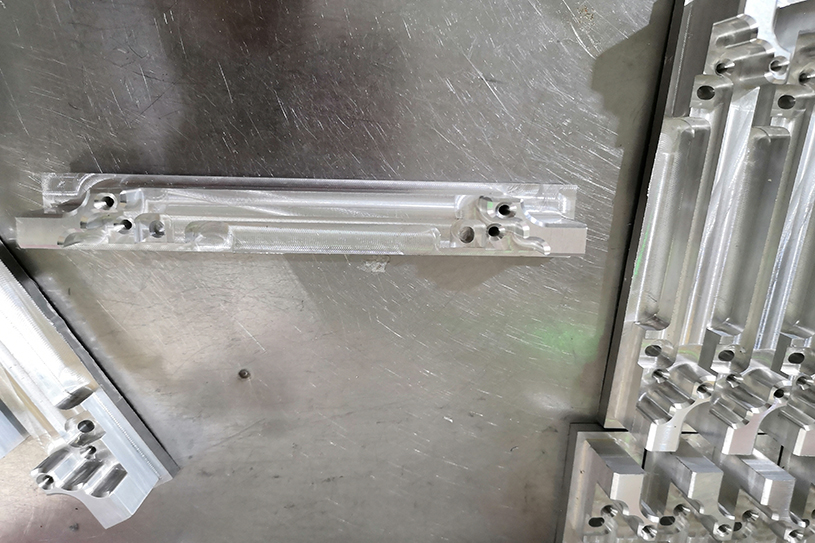

HSJ offers a wide range of services for custom aluminum components, including CNC machining, die casting, extrusion, and surface finishing. Their state-of-the-art facilities and skilled engineers ensure the highest level of precision and quality in every component they produce. Whether it's a complex engine part or a simple bracket, HSJ has the capability to manufacture custom aluminum components to the tightest tolerances and specifications.

Custom aluminum components are a vital component of modern automotive engineering, providing lightweight, durable, and versatile solutions for a wide range of applications. As the automotive industry continues to evolve, the demand for custom aluminum components will only grow. Companies like HSJ are leading the way in producing innovative and high-quality aluminum parts that drive the future of automotive engineering. By harnessing the advantages of aluminum, automakers can create safer, more efficient, and environmentally friendly vehicles that meet the needs of today's consumers.