Electrical terminal boxes are essential components in electrical systems, providing a secure and organized way to connect and protect wiring. Whether you're dealing with an external terminal box, a junction box, or an outdoor electric meter box, understanding how these devices function and are made can help you choose the right one for your needs.

An electrical terminal box, also known as a terminal block or junction box, is a housing used to secure and connect electrical wires. It acts as a central point where multiple wires can be terminated or spliced together. The box provides protection for electrical connections, preventing shorts, damage, and external environmental factors like moisture or dust from interfering with the system.

These boxes are commonly found in a variety of applications, including industrial, commercial, and residential electrical systems. Some specific types include:

External Terminal Box: Typically used for outdoor or external wiring connections, often built with weather-resistant materials.

Junction Box: A general-purpose box used to house electrical connections or wire splices.

Outdoor Electric Meter Box: A specially designed box to house electric meters, usually weatherproof and durable for outdoor installations.

The manufacturing of electrical terminal boxes involves several detailed steps to ensure the boxes are durable, safe, and functional. Here's an overview of the process:

The first step in producing a terminal box is to design the box based on the specific requirements of the application. This includes determining the size, material, and features such as waterproofing or fire resistance. Engineers also decide on the type of terminal block or connectors to be used inside the box.

Terminal boxes are made from materials like metal (steel, aluminum), plastic, or a combination of both. The material selection depends on the application—metallic boxes are often chosen for their durability and strength, while plastic boxes may be used for lighter applications or environments where corrosion resistance is important.

Once the material is chosen, it is cut to the required dimensions using CNC machines or laser cutters. The metal or plastic sheets are then shaped into the box, either by stamping or molding. For metal boxes, additional processes like bending or welding are often involved to form the structure.

To ensure the longevity and resistance of the terminal box, surface treatment steps are crucial. For metal boxes, processes like powder coating, galvanizing, or painting are done to prevent rust and corrosion. Plastic boxes are typically treated with UV-resistant coatings to prevent degradation from sunlight exposure.

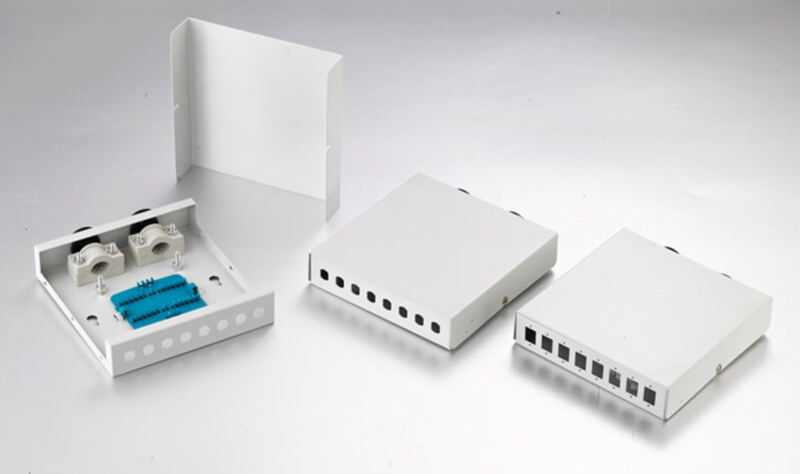

Once the terminal box casing is ready, it is fitted with internal components such as terminal blocks, screws, and wiring connectors. These are carefully arranged to ensure easy access for wire connections. Some boxes may have features like cable glands, mounting rails, or circuit breakers installed as part of the assembly process.

The final step in the production process involves rigorous quality control. The electrical terminal boxes are inspected for manufacturing defects, and the functionality of internal components like the terminal blocks and connectors is tested. Boxes are also tested for durability and resistance to environmental factors like temperature extremes, moisture, and physical stress.

There are various types of terminal boxes designed for specific purposes. Here are some of the most common types:

External Terminal Box: Often used for external electrical connections, these boxes are made from materials that can withstand harsh weather conditions, such as corrosion-resistant metals or weatherproof plastics. These boxes are ideal for outdoor lighting, streetlights, and other external electrical installations.

Junction Box: This is a versatile, general-purpose box used to connect and organize wires in a circuit. Junction boxes are commonly used in homes, factories, and commercial buildings to safely house wire connections and splices.

Outdoor Electric Meter Box: These are specialized terminal boxes designed to house electric meters in outdoor environments. They are weatherproof and lockable, ensuring the meter is secure from theft and protected from weather elements.

Electrical terminal boxes are a critical component in the safety, organization, and protection of electrical systems. Whether you're looking for a junction box, an external terminal box, or an outdoor electric meter box, it's important to understand the role each one plays in your electrical setup.

By understanding the manufacturing process and the different types of terminal boxes available, you can make better decisions when selecting the right products for your specific needs.

By investing in quality terminal boxes, you're not only improving the reliability of your electrical system but also ensuring a higher level of safety for both your equipment and personnel.