Die casting is a popular and efficient manufacturing technique used to produce precision metal parts with high dimensional accuracy. This process involves forcing molten metal into a mold cavity under high pressure, resulting in intricate shapes with smooth surfaces. Die casting products are found in a wide range of industries, from automotive to electronics, due to their strength, durability, and versatility.

Die casting is a manufacturing process in which molten metal is injected into a steel mold, called a die, under high pressure. The metal solidifies quickly inside the mold, creating a part with intricate features and a high-quality finish. The primary metals used in die casting are aluminum, zinc, magnesium, and copper alloys, as these metals offer excellent fluidity, durability, and resistance to corrosion.

A mold is designed, typically using steel, to create the desired shape of the part. The mold is precisely machined to include features like cavities, cores, and gating systems that allow the molten metal to flow properly.

Metal is heated to a molten state in a furnace. The temperature must be carefully controlled to ensure the metal flows smoothly into the mold.

The molten metal is injected into the mold cavity under high pressure using a plunger or piston. This step is crucial as the pressure ensures that even the finest details of the mold are captured.

After the part has solidified, the mold is opened, and the part is ejected. The die casting product is then subjected to any necessary finishing processes, such as trimming, cleaning, or coating.

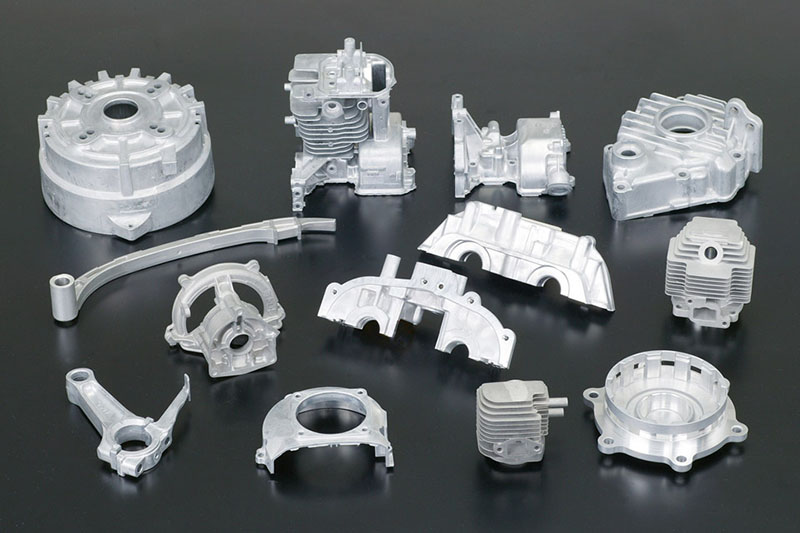

Die casting is used to produce a wide range of products, from simple parts to complex, high-performance components.

Die casting plays a significant role in the automotive industry by producing lightweight yet durable components, such as engine blocks, transmission cases, wheels, and housings for various automotive systems.

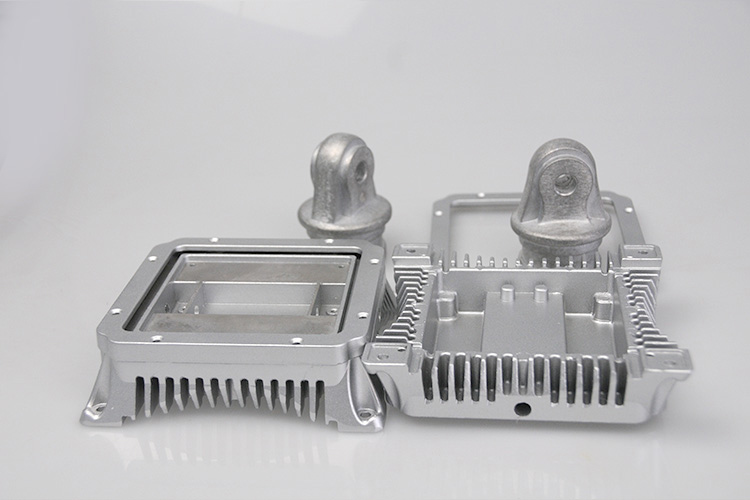

In the electronics industry, die casting is used to create enclosures and frames for devices like smartphones, laptops, and televisions. The ability to produce parts with high precision and excellent surface finishes makes die casting ideal for these applications.

Many industrial machinery components, such as gears, valves, and housings for motors and pumps, are made using die casting due to the process's ability to handle complex geometries and ensure reliability under heavy loads.

Die casting is used in the aerospace industry to produce lightweight and strong parts, including brackets, frames, and structural components, which are essential for ensuring the safety and performance of aircraft.

Die casting products in the medical field include parts for diagnostic equipment, surgical instruments, and medical devices that require high precision and biocompatibility.

In addition to electronics, die casting is used to create products such as kitchen appliances, power tools, and even decorative items.

Die casting produces parts with high dimensional accuracy and consistent quality. This is ideal for industries where precise components are critical, such as aerospace and automotive.

For high-volume production, die casting is cost-effective. The ability to produce large quantities of parts in a short amount of time results in economies of scale, reducing the overall cost per unit.

Die casting allows the creation of complex shapes that would be difficult or expensive to achieve using other manufacturing methods, such as machining or forging.

The process produces minimal waste, as excess metal can be reused in subsequent batches. This makes die casting a sustainable option for large-scale production.

Die casting products typically have a smooth surface finish, which often requires little or no post-processing. This is particularly beneficial in industries where aesthetics and functionality are important.

While die casting offers many advantages, there are some challenges to consider:

The initial cost of creating the molds can be expensive, especially for complex or large parts. However, these costs are offset by the efficiency of the process for high-volume production.

Not all metals are suitable for die casting. The process works best with alloys that have good fluidity and low melting points, such as aluminum and zinc, but it is less suitable for metals with high melting points like steel or titanium.

While die casting allows for complex geometries, there are still some design constraints to consider. The design must accommodate factors like wall thickness, draft angles, and parting lines to ensure successful mold creation and part ejection.